Do you run a manufacturing business?

If you are, then you must be aware that adapting to the digital era prepares you to keep up with the competition.

The problem is that the intricacy of implementing the digital solutions will disrupt your day-to-day operations. As a result, it hinders the scaling process while you also need to deal with cost barriers and low-skilled workers.

Fortunately, this is where Odoo ERP features for manufacturing businesses fit into the equation.

This article will emphasize the benefits of ERP features of the Odoo Manufacturing module that specializes in regulating all aspects of large-scale production for your business needs. However, we’ll briefly touch upon its integration with some relevant core modules that are just as beneficial, such as Purchase, Shop Floor, Barcode, PLM, and Inventory.

Odoo ERP features for manufacturing industries

Enterprise Resource Planning (ERP) is software that helps to run and manage all the core business processes of an organization. ERP implementation improves processes ranging from finance, manufacturing, and supply chain to procurement. A suitable ERP, like Odoo, integrates these processes into a single system, which allows you to see all your business processes in one place.

Here are some of the best Odoo ERP features for manufacturing business:

1. Manufacturing execution and shop floor control

Production cannot start without the materials to create your products. Bill of Materials is one of the ERP features for manufacturing businesses that allow companies to define the components, quantities, and operations required to produce their finished products. This feature also helps create variants, by-products, and kits, and manage the cost and quality of a product.

Other important features for execution are housed under the Manufacturing module . The Manufacturing Resource Planning feature helps manufacturers plan and manage their production capacity. Remember that the timely availability of materials is the key factor in meeting production targets.

With Odoo Manufacturing, its IoT Boxes integration feature enables you to connect your machines and devices to the system using the Internet of Things (IoT) technology. So you can control your machines remotely, collect data from sensors, and automate actions based on your predefined rules on production.

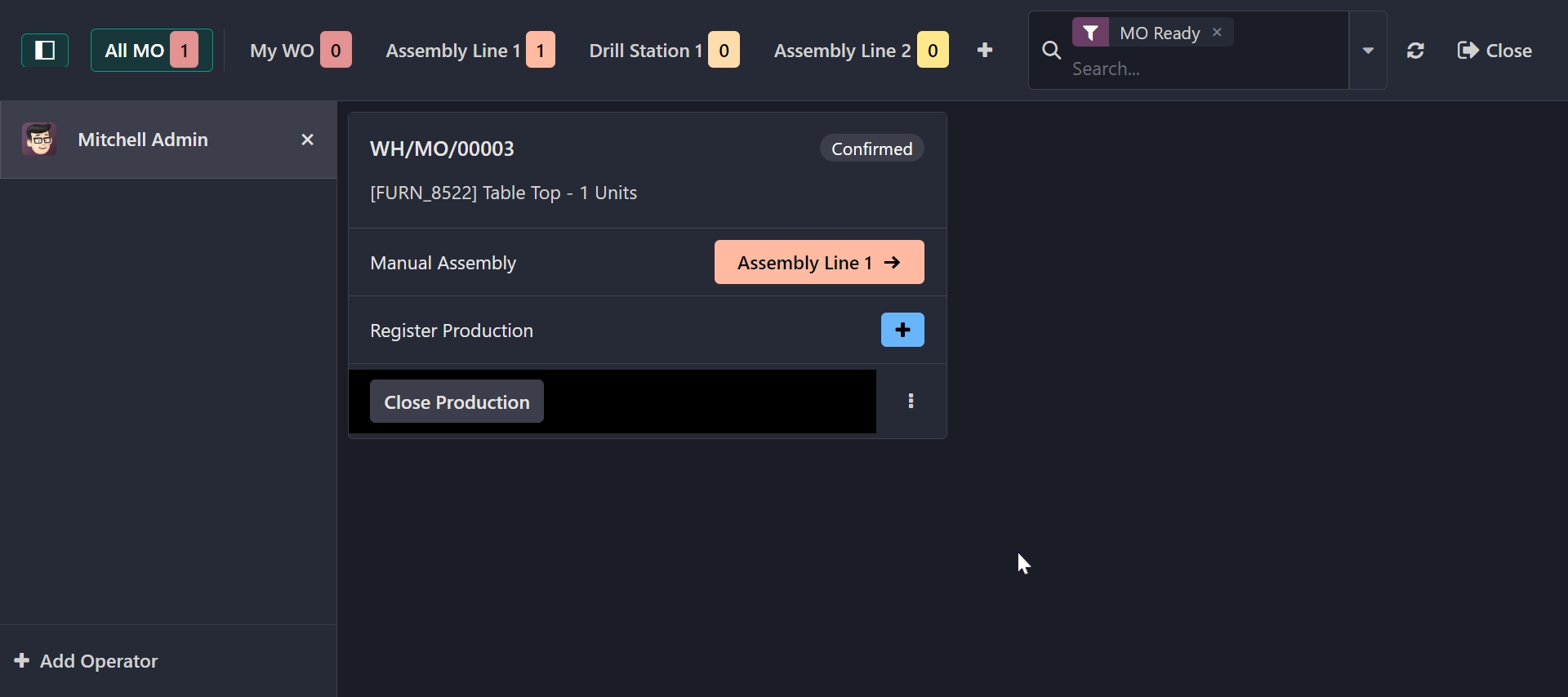

Together with the Manufacturing Execution System (MES) feature in the Shop Floor module, operators and supervisors can control their work orders and work centers, track the time spent on production tasks, trigger maintenance operations, and report quality issues - all from the convenience of their tablets.

Learn how to wield IoT

not only to control your industrial appliances but also to improve your inventory management.

2. Quality management and compliance

The biggest quality check issue in manufacturing is the lack of standardized procedures. Without clear and consistent guidelines for quality control, manufacturing operations can become chaotic and unpredictable, resulting in time and material waste.

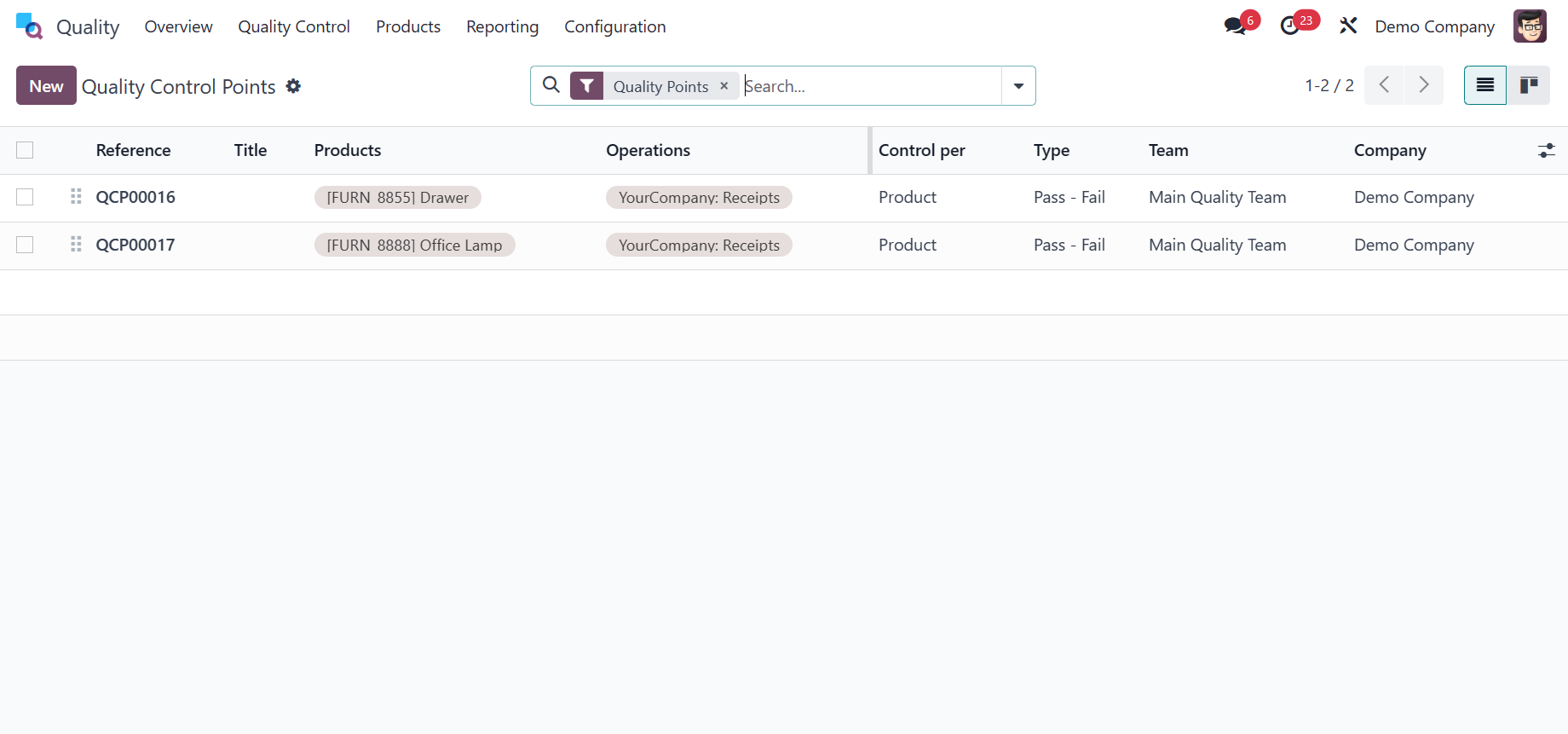

Quality Control feature in the ERP system to mitigate the existing issues. Companies can document quality control requirements with customizable plans that specify test methods, acceptance criteria, and steps for handling defects.

Perform quality checks throughout the manufacturing process and inventory movements with the Quality Checks feature. Your QC Inspectors will be able to automate the frequency of quality inspections. Therefore, manufacturers can reduce the cycle time and the labor cost of quality checks, and increase the throughput and the accuracy of quality results.

Odoo also has Quality Alerts so your QC Inspectors can flag product quality issues easily, and assign them to the responsible quality team or person. Then, they can take advantage of the Quality Worksheets to fill out QA forms, take pictures, or scan barcodes to complete quality checks.

3. Product life cycle management, production planning, and scheduling

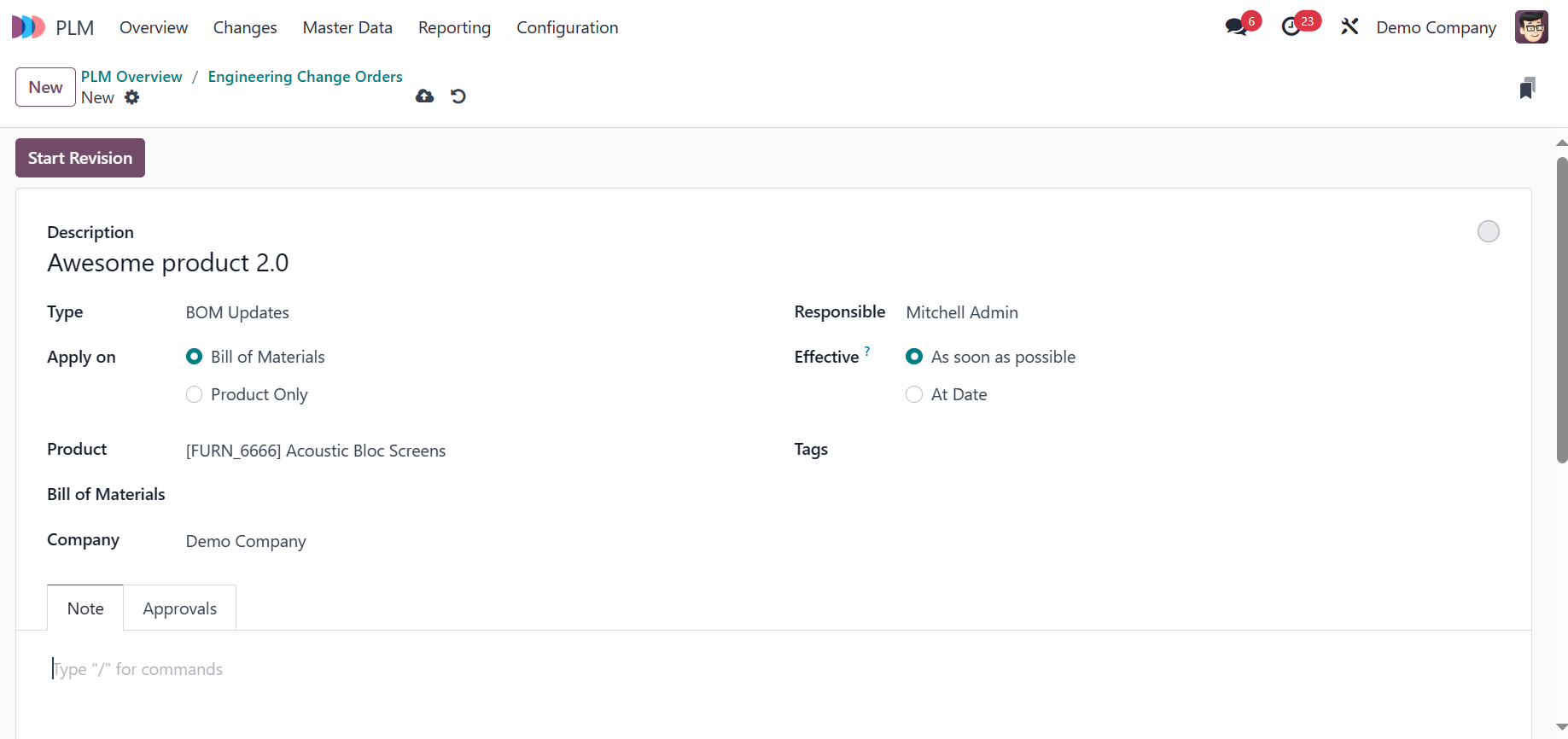

Product lifecycle management is crucial to anticipate potential issues that may arise during the product development and marketing stages. Odoo ERP features for manufacturing businesses help manage testing, collaboration, and iteration of products.

One of them can be found in the Product Lifecycle Management (PLM) add-on module. The tools in the module allow companies to make revisions either in the Bill of Materials or just in the product in the manufacturing stage and beyond - like in the marketing and post-launch support stages.

Another common issue in production planning in a manufacturing company is the difficulty of predicting future demand for a product or service. Therefore, it is recommended to utilize Odoo 17’s AI-empowered Demand Forecasting feature in the Inventory module. The feature uses machine learning to analyze historical data and predict future demand patterns, so production planning can become more accurate and efficient.

With the forecast in hand, master schedulers in your company then can use the Master Production Schedule feature in the Manufacturing app. The element allows them to plan production based on the demand forecast and safety stock target.

4. Inventory and warehouse management

When manufacturers do not have adequate visibility and control over their inventory levels and movements , they won’t be able to track their losses due to unpredictable events. Odoo can help track inventory movements to control the flow of your products across your warehouses, locations, and partners. By using the Odoo ERP module, Barcode, workers can use barcode scanners, IoT devices, or tablets to scan products and locations and record inventory operations in real-time.

Just as important, optimize your inventory levels with Reordering Rules. Plan and automate your replenishment orders, using demand forecasting, minimum stock rules, make-to-order, or reordering rules. The feature also allows companies to launch replenishment orders for products and components, and track the actual and suggested replenishment quantities. That way, companies will always have the materials to keep producing based on customer demand.

The Odoo manufacturing ERP capabilities in Warehouse Management allow the creation and configuration of multiple warehouses and locations. It can also define the hierarchy and structure of your storage spaces. This feature allows you to manage your inventory across different physical or virtual locations and set up rules and routes for the movement of your products and materials, which maximizes your warehouse space.

5. Supply chain and procurement management

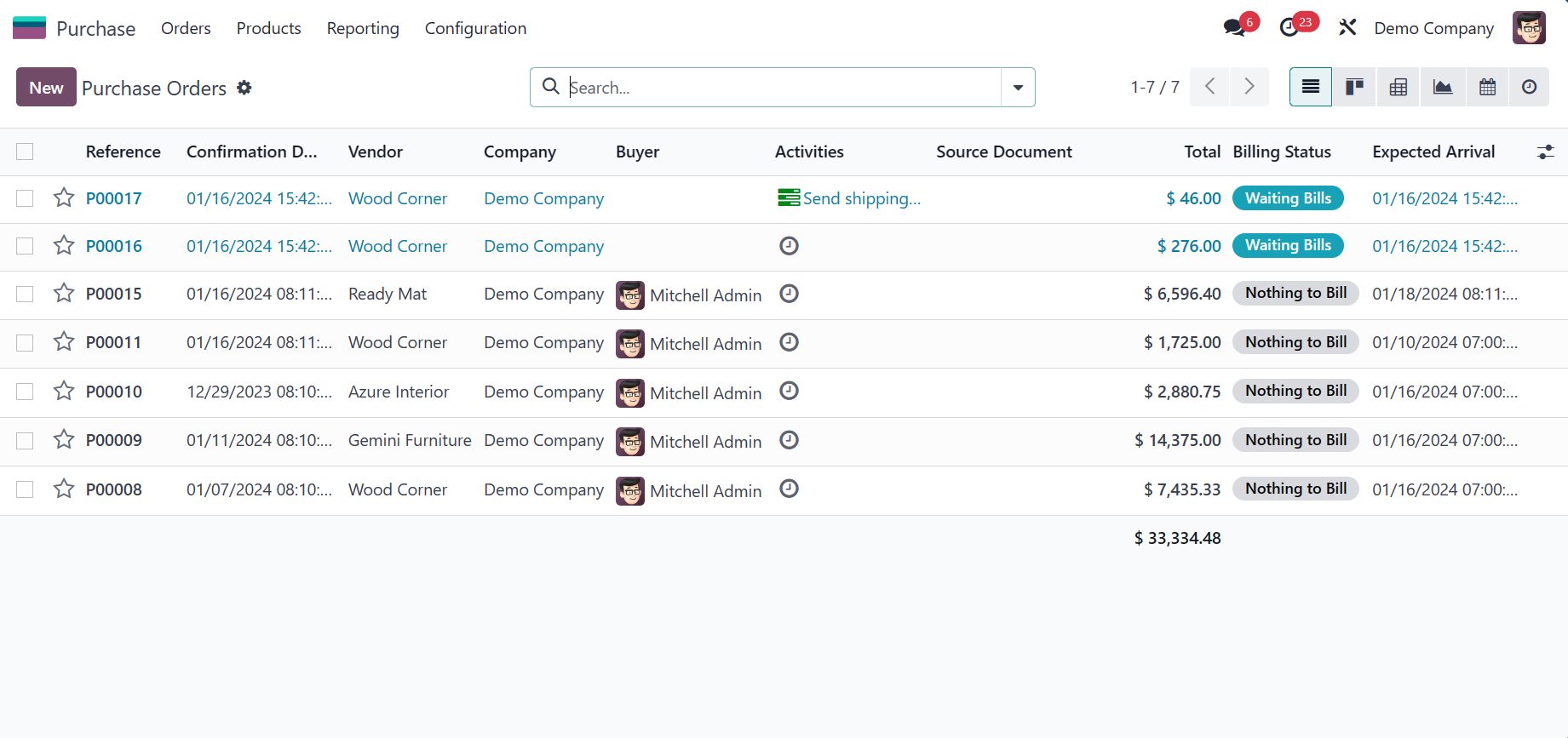

Purchasing effectively saves costs. The Purchase Management feature in the Purchase module streamlines the procurement process by allowing manufacturers to automate and streamline their purchasing activities. It is also important to help manufacturers maintain good relationships with their vendors to ensure on-time raw materials delivery.

The same module also housed the Vendor Consignment feature, which is specifically designed to manage consignment stock provided by suppliers for supply chain enhancement. Companies no longer need to hold excess stock, which optimizes inventory management. Not to mention the Dropshipping feature is also great for the same reason since it allows you to regulate how you sell your products without stocking them. Manufacturers can now expand their product offerings while reducing costs and increasing flexibility.

Speaking of supply chain management, the Manufacturing module has Advanced Routing to define complex routing sequences for manufacturers’ production processes. Utilizing this feature reduces production lead times by optimizing the flow of materials and resources. Additionally, you might want to consider utilizing Odoo’s ERP features for inventory management to elevate your supply chain management further.

Odoo Manufacturing ERP system capabilities are everything you need and more

Manufacturing ERP software features are designed to provide an integrated one-stop solution for business operations for manufacturers. Imagine an ERP solution that fosters new groundbreaking innovations and increases productivity. By having an efficient system that automates common tasks, your people have more time to create new ideas and solutions to contribute to the business. You can expect the acceleration of product delivery and production since ERPs like Odoo allow tracking, scheduling, and optimizing manufacturing processes from start to finish.

By default, Odoo manufacturing ERP features promote a business’s ability to adapt to the rapid changes in technology - therefore, fulfilling your customer needs faster. Odoo is also one of the most versatile ERPs, which makes it easy to tailor the ERP to support your business models and how you imagine your enterprise operates. With the right partner and ERP, your system will help overcome the barriers of cost, skills, security, and complexity that come with digitalization in a manufacturing environment.

Contact Portcities

to implement Odoo ERP for manufacturing. With extensive experience in implementing

Odoo for manufacturing businesses

, be assured that you’ll have a seamless transition and tailored solutions that optimize your supply chain and procurement processes.